I have a new toy that came in two weeks ago: it’s a Full Spectrum 40W hobby laser cutter! It has been sitting in the shipping box for all this time. This weekend I finally gather everything I needed to set it up, and here are some fresh-made engravings:

Not too bad for the first try, isn’t it?

Impression. My order was handled very quickly. I placed the order on a Tuesday after 5pm and it was shipped the same day! A big thumb-up to the Full Spectrum team. A week later, the box showed up at my door. It’s quite big and heavy. I mean, this is already the least expensive, hobby level model on the market. I can easily imagine how daunting the professional level ones must be.

Setup. The build quality is pretty good. The exterior could probably use some more sexy design, but at its price level, I have no complaint. To set it up, I bought a stainless steel table from Ikea, a 5-gallon bucket with cover from Lowes, and five gallons of distilled water. The user manual stressed everywhere that you must use distilled water and not tap water. It is used to cool down the laser tube. I guess distilled water is crucial to avoid sediments.

The user manual is a bit confusing and not entirely consistent. Some pictures do not match my model I ended up having to check some youtube videos and forum posts to figure things out. Also, the instructions for installing the beam combiner are almost unreadable due to low toner. This is a bit disappointing. The good news is that these instructions are all available online, so it’s not a big deal.

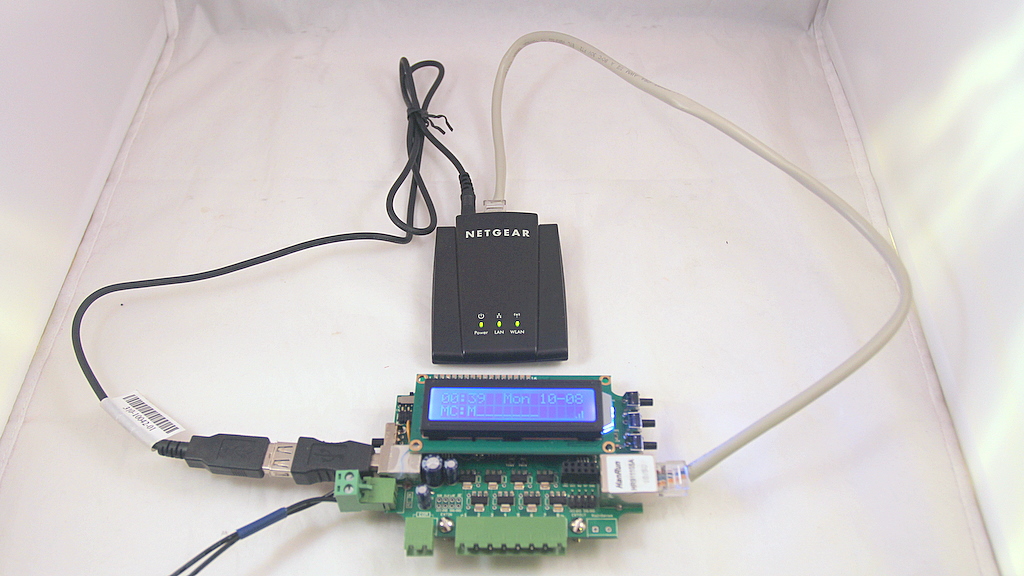

There are three peripheral devices I set up first: air compressor, water pump, and exhaust fan. Air compressor is the easiest: just connect the air tube and that’s all. For setting up water pump, I cut three holes on the cover of the bucket, so that the in/out tubes and the power cable can go through the cover easily. Then I placed the water pump in the bucket, and poured 5 gallons of distilled water. The exhaust fan is also fairly easy to set up. The only tricky part is to find a way to vent exhaust air to the outside. My solution is to use a piece of cardboard paper and cut it to the right size so that it can fit tightly on my window. Pictures are included:

Running. The first thing to do is to manually move the Z-table in order to get the laser focused onto the engraving surface. I followed the instructions to do a fire test and it worked right away. Keep in mind that the water pump, air compressor, and exhaust fan MUST be running before the laser fires. Also make sure that the emergency stop is deactivated, and the laser switch is activated. The control is done through USB port, which is very convenient. (I remember my hobby CNC machine requires a hardware parallel port, which was a pain to find). The software is only available on Windows. Since I am mainly using Linux these days, I had to salvage an old Windows PC for this. I suspect I can probably run it through a Virtual Windows on my Linux machine too. The software is reasonably good. It did give me annoyance like hanging and crashing, but nothing that can’t be fixed by restarting the laser cutter and software. Here is a video demo of the machine in action:

As you can see, my first test case is to engrave the OpenSprinkler logo (courtesy of Nathan Johnson) onto the project enclosure. It took me a few tries to find the right laser power level and speed. No rocket science. The enclosure material is probably not best designed for laser engraving, because it can easily burn and produce a greenish color. But at the appropriate laser intensity, it looks reasonably good.

The next order I ship will include this engraved project enclosure 🙂 I can probably start making a small batch of engraved enclosures if it turns out to be reasonably productive.

The next order I ship will include this engraved project enclosure 🙂 I can probably start making a small batch of engraved enclosures if it turns out to be reasonably productive.

My next steps are to try laser cutting, and installing the beam combiner. Overall I am pretty happy with this new toy. Given that this is the first time I’ve ever used a laser cutter, I would say the installation and initial tests went very smooth. Again, a thumb-up to the Full Spectrum team.