Last night, a heavy snowstorm mixed with strong winds hit Massachusetts. Many cities lost power, due to fallen trees and broken power lines. Snow in October? Rare and totally unexpected. When I woke up this morning, I found huge tree branches fallen everywhere. Driving through any road requires special attention. This is a picture of a tree in front of my office building that got split in half:

The damage is clearly much more serious than the much anticipated Hurricane Irene in August, which caused very little harm. Even now I still don’t have power at home, and more than 60% of the city is out of power. Looks like I might have to stay at the office for tonight…

Anyways, due to the power outage, the web server went down for almost an entire day. I got a couple of emails about what’s happening. The good news is that it’s now back online, so that’s a relief.

So what did I do last night? Well, most of the night we were just sitting in the dark, with candles, and chatted. That’s not the whole story though. The rest of the time, I was…having fun with flashing LEDs! How come? Well, we had planned a small gathering with friends to carve pumpkins together, and I came up with the idea of making a few flashing LEDs to decorate the pumpkins. I was lucky enough to finish making two pairs of them before the power went out. We didn’t have any pumpkins to decorate, but I put one pair on a plush Totoro, and made an angry, dark Totoro. Check it out (sorry that the video is really short because my phone was running out of battery!):

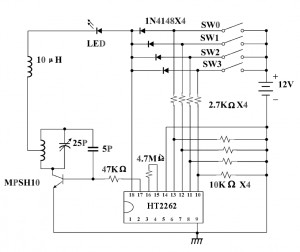

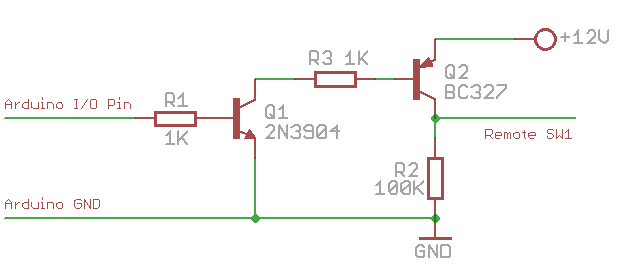

So how did I make the flashing LEDs? It’s by using a circuit called the multivibrator. Sounds funny? Well, hold your thought… The multivibrator is a very basic oscillator, involving only two transistors, two capacitors, and four resistors. In the next blog article, I will explain how to make it and the principles behind it. There is nothing particularly novel, and most people would probably go with a 555 rather than transistors. But it’s really fun to learn how such a basic circuit works. Stay tuned!