I had an amazing day visiting Worthington Assembly Inc. (WAi) — an electronics manufacturer / circuit assembly company located in South Deerfield, MA. It’s only 15 minutes of driving from Amherst, where I live. I first saw their business name when I was reading Ryan O’Hara’s post about how he got his RGB-123 LED matrices manufactured. I must have had a lousy day then, because I failed to notice the location of the company, and had always thought it’s in Boston. Then last night when Andrew Seddon, CEO of CircuitHub.com, pinged me about PCB manufacturing and mentioned WAi, I suddenly came to realize that they are located right next to me. Gosh, I felt completely dumb that I didn’t find this out earlier!

Anyways, I couldn’t bear with the temptation to check out their facilities, so I paid a visit right away this morning. It really made my day — the beautiful pick and place machines, conveyor belt reflow oven, selective soldering machine, it’s like a dream circuit assembly house I’ve always wanted. Chris Denney (CTO) gave me a tour around the house. I was too engaged in the conversations and didn’t take as many pictures as I wanted. But here are a few:

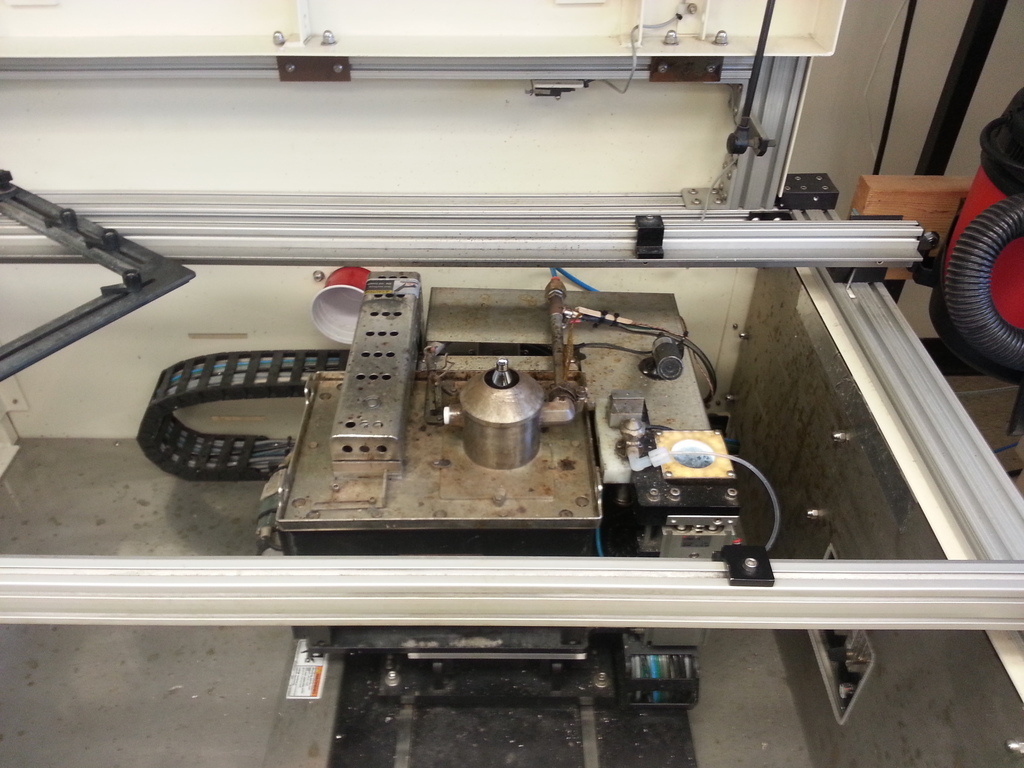

On the left, Quad QSP-2 picker that’s being retired (at the end of the picture is their Vitronics Soltec reflow machine); on the right: through-hole component insertion machine.

MyData picker that’s currently in service. This one can pick 8 components at a time, and has a super fast vision system that does alignment in real time. It also has a mechanical alignment system, and a component checking system that can read component values (e.g. resistance, capacitance) on the fly. Amazing!

Selective soldering machine, and PCB cutter.

Very satisfying. I can even imagine the next batch of OpenSprinkler to be assembled right here. Then I can just drive up in 15 minutes to pick up the order. How cool is that 🙂 They take both large-quantity and small-quantity orders, down to even just 1 board, surprisingly. Of course the cost of making just 1 board would be quite high, compared to making 100, where the same overhead cost will be amortized.

Right now they are in partnership with CircuitHub.com to make the service available to makers and hardware startups. If you have circuit assembly need and don’t have the resources to make them yourself, or if you have the resources to make a few but not hundreds, you should definitely give it a try. Just log in to CircuitHub.com (with your dropbox account) and upload some Eagle project files. The user interface is very clean and friendly. It links to Octopart.com to grab component prices in real-time. You can then adjust the order quantity and lead time. Kudos to Andrew for building such a slick website.

I was very well treated, had Polish beer with Neil, Rafal, and Chris; and by the end of the day, I even got two free T-Shirts. Cool. Picture moment!